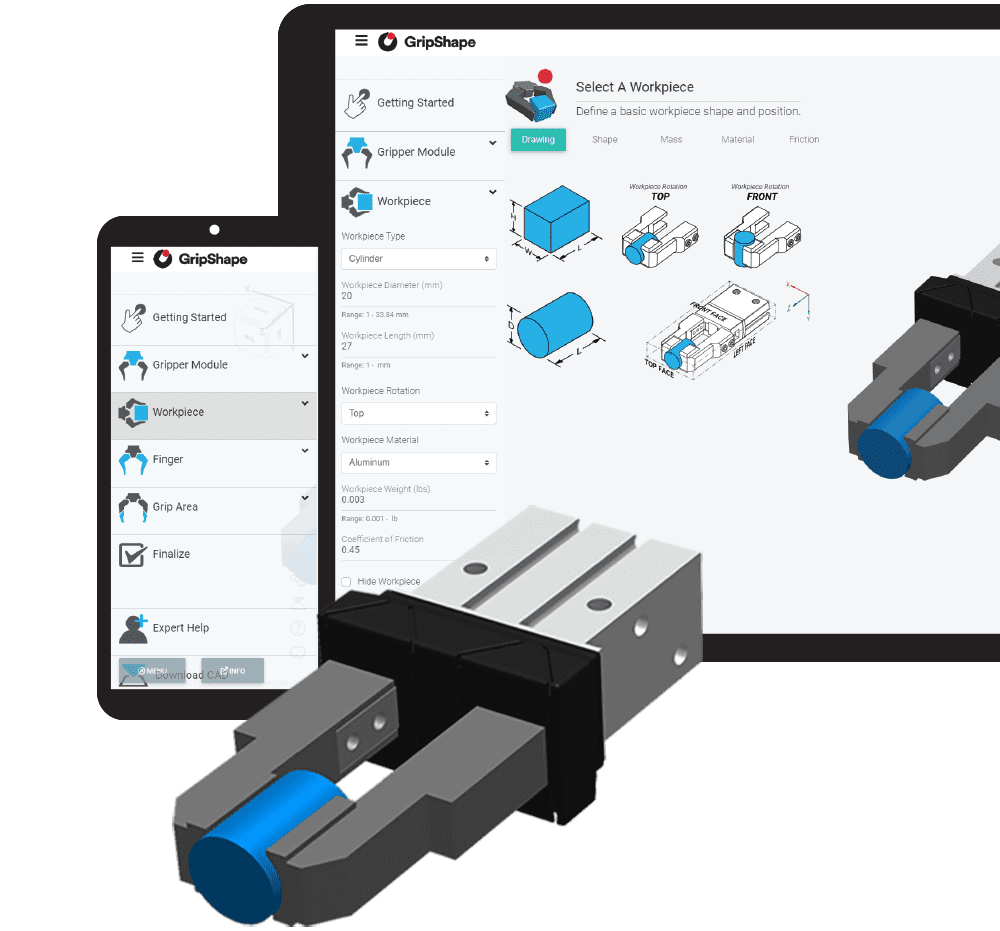

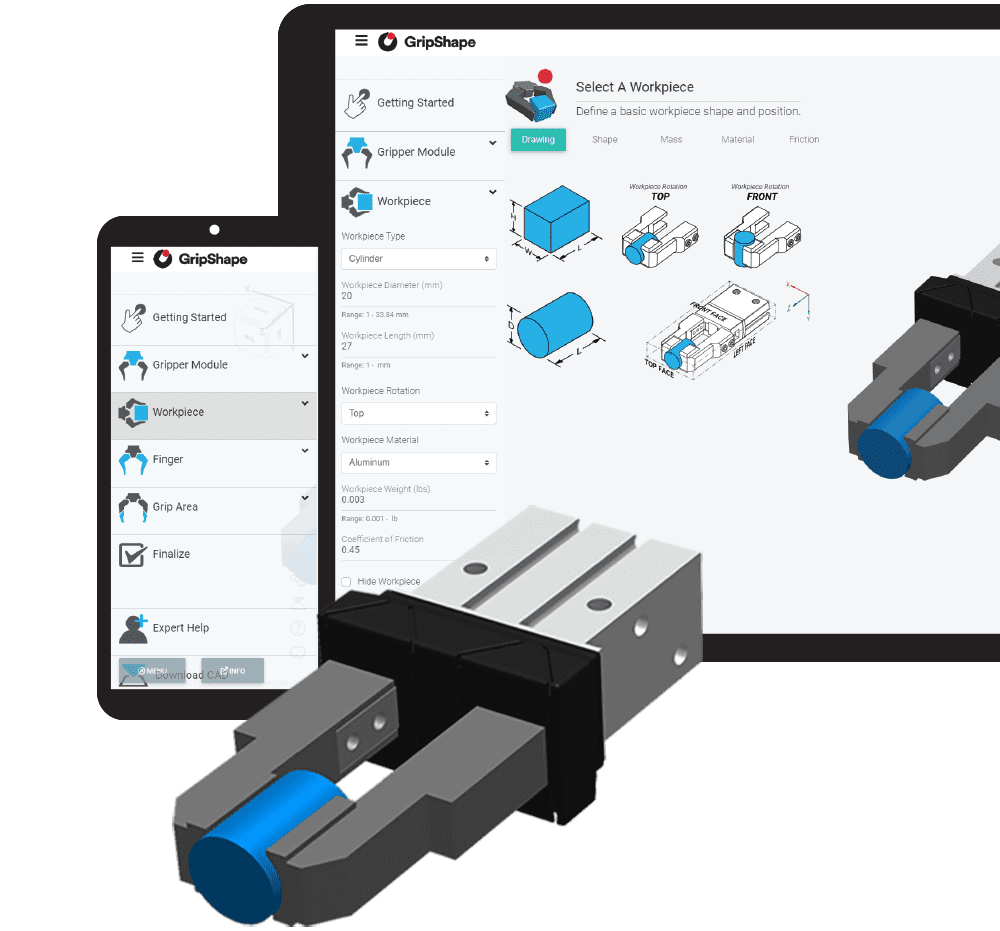

GripShape's Online

Design Tool

Need a custom gripper? Reduce your design time by up to 95%. Select your gripper module and let GripShape’s advanced configurator go to work generating the finger geometry for you.

Interested in our standard parts or just want more information

on how our experts can help with your design project?